Chilled Mirror Hygrometer Temperature Depression Explained

There is often confusion about the dewpoint measurement range of chilled mirror hygrometers and their temperature depression range. The hygrometer dewpoint measurement range and the temperature depression are interrelated, but they are not the same. The hygrometer’s dewpoint range is determined by the amount of temperature depression that the hygrometer’s sensor is physically capable of, plus the actual sensor temperature as it is effected by the ambient temperature, the sample gas temperature, and any ancillary cooling of the sensor (i.e. coolant flowing through the sensor’s cooling jacket).

Chilled mirror hygrometers determine the dewpoint temperature of a gas or gas mixture by cooling the sensor’s mirror until dew or frost forms on the mirror’s surface. The sensor then uses its optical components sensors to determine that dew or frost has formed, and stabilizes on the temperature at which the dew/frost is just forming. That is by definition the dewpoint temperature.

The dewpoint temperature is a measurement of the amount of water vapor in a gas. For any dewpoint temperature there is a singular aqueous vapor pressure. Dewpoint temperature is a primary measurement that can be used to calculate other moisture parameters including parts per million or relative humidity if pressure or temperature are known.

The sensor’s mirror in most chilled mirror hygrometers is cooled by a thermoelectric cooling device. Thermoelectric cooling is the cooling effect that occurs as a result of current flowing between two different conductors or semiconductors; heat is produced at one juncture and a cooling effect at another juncture, creating a temperature differential. This can be used to transfer heat from one place to another. A system that uses this effect is called a Peltier heat pump. 1

Thermoelectric coolers come in various ranges of cooling capability. Depression is the potential difference in temperature between the temperature of the sensor base and the cooling capability of the thermoelectric cooler. The sensor temperature could be ambient or the sample temperature or the temperature of a coolant flowing through the sensor’s cooling jacket. Multiple thermoelectric coolers can be used together in stages to increase the available amount of temperature depression.

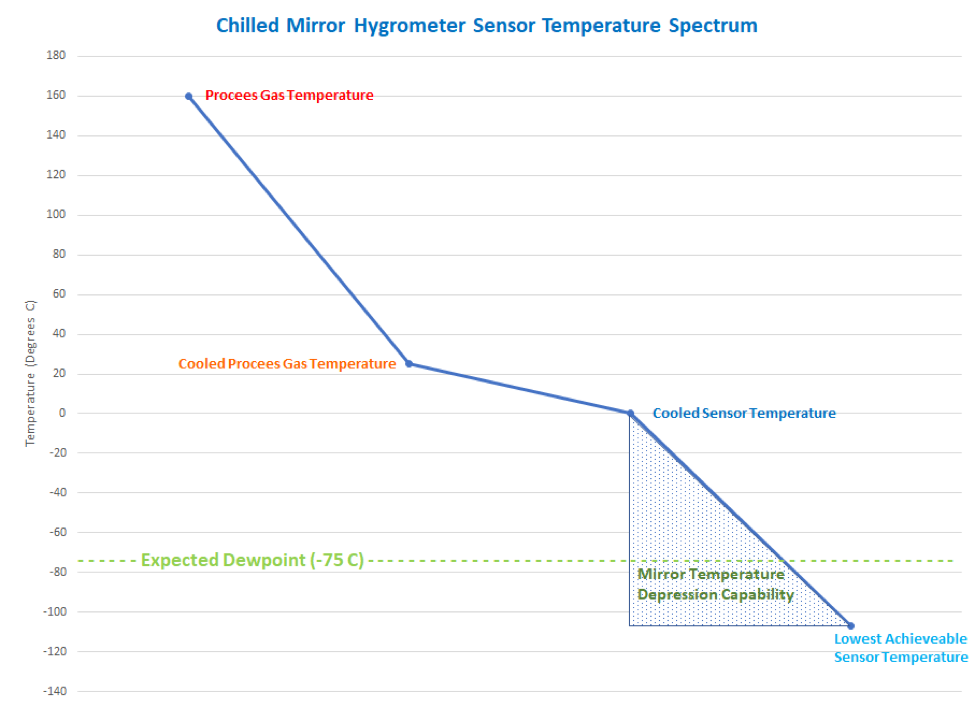

Example: An oxygen production plant purchased an Edgetech Instruments chilled mirror hygrometer having a three-stage thermoelectric cooler, for a gas dryer application with an expected dewpoint range of +20°C to -75°C. The challenges were a high sample temperature of +160°C and a low expected dewpoint temperature of -75°C. This represents a mirror cooling range requirement of 235°C. The three-stage thermoelectric cooler in the hygrometer had a depression capability of 115°C.

In this example it is clear that the depression capability of the three-stage thermoelectric cooler was not sufficient to determine the dewpoint from the highest sample temperature of +160°C to the lowest possible dewpoint temperature of -75°C. However, two installation adjustments solved the problem.

A representative sample was drawn from the process through a three-foot, ¼” stainless steel tube. The sample temperature dropped to approximately ambient conditions at 25°C. The ambient temperature was above the highest expected dewpoint of 20°C, so line condensation did not occur in the sample line.

If condensation in the sample line became a problem, heat tape on the sample delivery line, to keep the sample temperature above dewpoint temperature, would have been recommended. In this case however it was not needed.

To achieve a -75°C dewpoint measurement, a further temperature drop was needed. The oxygen production plant used a sensor coolant, chilled ethylene glycol, flowing through the sensor’s cooling jacket to drop the temperature of the sensor to 0°C. This became the “top” end of the depression range.

The thermoelectric cooler in this example had a 115°C cooling capability with auxiliary liquid cooling if it was starting at 25°C ambient. A thermoelectric cooler will lose approximately 1°C for every 3°C drop in ambient temperature. In this case, the sample temperature was dropped from the ambient of 25°C to 0°C, or a total of 25°. Therefore, the thermoelectric cooler lost about 8°C cooling capability. At 0°C, the three-stage thermoelectric cooler had a depression capability of approximately 107°C from the 0°C sensor temperature. It was well within the lowest expected dewpoint of -75°C.

References: 1; https://www.techopedia.com/definition/14769/thermoelectric-cooling-tec