Chilled Mirror Hygrometry, a Technology for Process and Lab - Part 4

Part 4: Operating Principles of Chilled Mirror Hygrometers

The temperature at which water vapor in a carrier gas condenses onto a plane surface as liquid water or solid ice is called the dew point temperature or the frost point temperature if below freezing, respectively. The dew or frost point temperature is declared when the condensed layer is in equilibrium with its vapor phase. The chilled mirror hygrometer determines this temperature by optoelectronic means. When light reflected off of the mirror surface is non-changing in time signifying that the condensed layer is neither growing nor diminishing.

The temperature at which water vapor in a carrier gas condenses onto a plane surface as liquid water or solid ice is called the dew point temperature or the frost point temperature if below freezing, respectively. The dew or frost point temperature is declared when the condensed layer is in equilibrium with its vapor phase. The chilled mirror hygrometer determines this temperature by optoelectronic means. When light reflected off of the mirror surface is non-changing in time signifying that the condensed layer is neither growing nor diminishing.

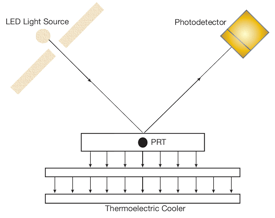

Figure 1. A CMH system shown diagrammatically; the temperature of the mirror is measured by a highly accurate and precise PRT; the mirror is cooled by a thermo¬electric cooler (TEC), and the dew or frost layer thickness is controlled by an opto-electrical servo-controller. The control unit, not shown, provides all necessary algorithms.

The schematic diagram in Figure 1. depicts the chilled mirror hygrometer system. Figure 2. is an example of a chilled mirror hygrometer configured with an insertion probe used in process or lab applications. Accuracies of chilled mirror hygrometers can be ±0.1°C dew/frost point over a temperature range of 90°C to -90°C, with no hysteresis. This is accomplished by means of a very sensitive optoelectronic system and a platinum resistance thermometer (PRT) that measures the temperature of the mirror at the declared dew/frost point.

The schematic diagram in Figure 1. depicts the chilled mirror hygrometer system. Figure 2. is an example of a chilled mirror hygrometer configured with an insertion probe used in process or lab applications. Accuracies of chilled mirror hygrometers can be ±0.1°C dew/frost point over a temperature range of 90°C to -90°C, with no hysteresis. This is accomplished by means of a very sensitive optoelectronic system and a platinum resistance thermometer (PRT) that measures the temperature of the mirror at the declared dew/frost point.

Figure 2. An example of a chilled mirror hygrometer configured in an insertion probe for O-ring sealed duct mounting; the unit, the model D Series Probe with a Dew Master control unit, provides several output signals e.g. RS232, 4-20 ma, 0 to 10 Volt, offers unit interconversions like ppmv, dew/frost point, gr/lb, etc., and comes equipped with alarm settings.